SEAL ASSURANCE SOLUTION

Enhance your CCI strategy

Assuring container closure integrity is a product life cycle journey.

SmartSkin’s Seal Assurance Solution supports you through every stage by giving you unique insight into the top load and sealing forces your containers experience through the packaging process. Develop a better understanding of capping and crimping equipment, identify risk areas, and study how process variability affects your container closure system so you can help ensure that drug products remain protected long after they leave your line.

SMARTSKIN DRONES

Real-time top load and seal tightness measurements.

SmartSkin’s Seal Force drones run on your line alongside empty or water-filled production containers through capping and crimping machines. All drones are designed to match your containers’ exact specifications, so you can get accurate, reliable data on the top load and sealing forces applied through the process and beyond.

Use a single drone, or an entire fleet, to measure the top load force applied by each capping head, sealing forces applied through crimping, shock, tilt, and rotation through the entire process, and seal tightness for up to one week after crimping.

QUANTIFEEL SOFTWARE

Actionable insights for complete capping optimization.

QuantifeelTM Seal Assurance software comes pre-installed on a provided tablet and runs in conjunction with your SmartSkin drone as it traverses the line. No lengthy IT setup or equipment integrations are required. Use the tablet, or an iOS device, with the software to collect and analyze force data from a single drone or a fleet to simultaneously measure each capping head.

QuantifeelTM uses a specialized algorithm to analyze 1000s of data points and provides you with real-time top load measurements through the process and sealing force measurements for up to one week after crimping so you can identify and optimize the critical parameters within your capping and crimping machine.

Frequently asked questions

Assess. Verify. Optimize

Get a unique look into the top load and sealing forces applied through capping and crimping machines.

Run a SmartSkin Seal Force drone alongside production containers and use the provided tablet with Quantifeel™ Seal Assurance software to collect top load, seal force, shock, and motion measurements through each capping head at production speeds.

See exactly what forces are applied to your containers through production and monitor the seal force for up to a week after crimping.

Key Features

Multi-drone fleet

Run multiple Seal Force Drones through your machine simultaneously to compare the forces applied by individual capping heads.

Automated reports

Eliminate manual data analysis. As soon as the run is complete view the automated charts and reports to verify consistency and identify issues, on-the-spot.

Fast setup

No baselining or integrations required. Simply follow the step-by-step instructions on the provided tablet to connect the drones and start collecting data.

Versatile

Leverage individual or fleets of Seal Force Drones to investigate and optimize stoppering, capping, crimping, stacking and warehouse handling processes.

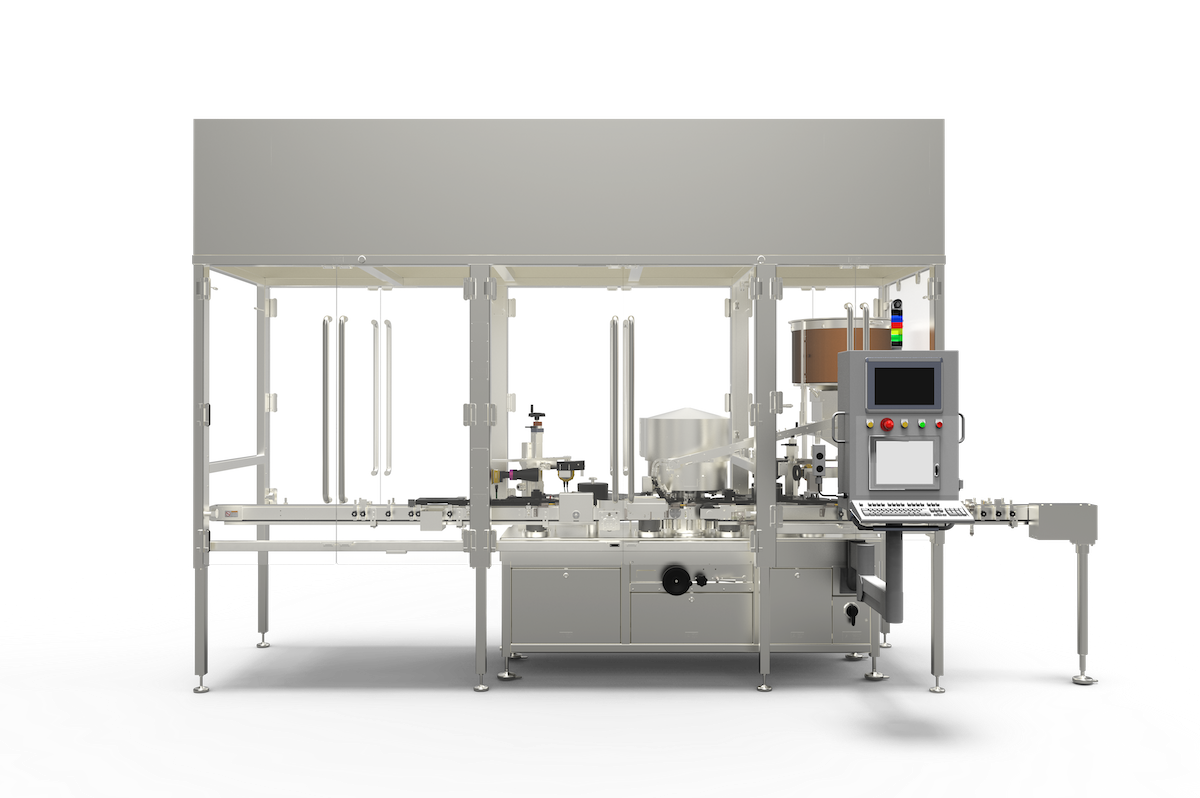

TECHNOLOGY PARTNER

Genesis Packaging Technologies

Genesis Packaging Technologies offers advanced vial sealing equipment for the packaging of critical injectable pharmaceutical products as well as specialized Residual Seal Force testing equipment.

As an authorized SmartSkin reseller, Genesis’ vial handling expertise and leading-edge manufacturing equipment paired with SmartSkin’s Seal Tightness technology is the perfect combination to help you meet Annex 1 regulations and enhance your seal assurance strategy.