Quantify your containers’ experience on the production line.

Experience your line from the inside — SmartSkin reveals what your containers feel, so you can optimize every run.

Data-driven analysis of forces impacting your products.

SmartSkin’s solutions combine innovative digital container twins and proprietary software to provide manufacturers with actionable data that helps them improve productivity, saving them valuable time and money.

Apply data insights to detect challenges, resolve inefficiencies, and elevate line performance.

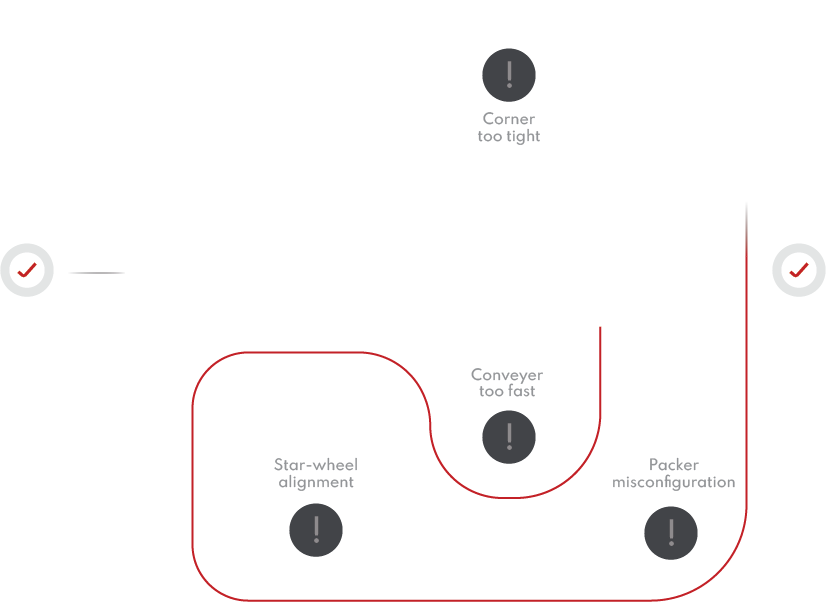

Pinpoint the root cause of damage on your line.

Our intuitive, easy-to-use container twins give you unprecedented visibility into your manufacturing line. By traveling through your conveying, filling, and packaging systems just like a real container, they precisely measure the magnitude and location of damaging forces in real time.

Whether it’s pressure, impact, vibration, or tilt, SmartSkin captures the data your containers can’t tell you — helping you pinpoint problem areas, reduce damage, and fine-tune your line for optimal performance and efficiency.

Technology built for your environment.

Get a complete overview of your line’s container handling performance. Quickly and easily pinpoint problem areas and present information in a powerful and accessible way.

Whether you want to see your historical line performance for better managerial decisions, compare your line to a generated industry standard, diagnose issues within machines that are otherwise unknown, or improve your overall product quality, we can get you started.

Solve your container handling issues today.

Latest from SmartSkin

Welcoming Dave Smith – Expanding SmartSkin’s Strength Across Europe

SmartSkin – Year-End Review 2025

Celebrating Impact: SmartSkin Recognized for Innovation in New Brunswick

SmartSkin Launches Pharma Seal Assurance Solution to Deliver Real-Time Insights into Container Closure Integrity and Capping Performance

Pharmaceutical

Pharmaceutical  Food & Beverage

Food & Beverage