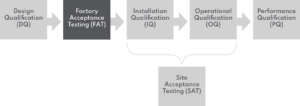

The Heart of Equipment Qualification: Factory Acceptance Testing (FAT)

In the realm of manufacturing, precision and reliability are non-negotiable. Ensuring that manufacturing equipment meets the highest standards is not just a best practice; it’s a critical necessity. At the core of this assurance lies Factory Acceptance Testing (FAT).

The FAT Journey: A Closer Look

-

A Versatile Starting Point

FAT serves as a versatile starting point for equipment qualification. Even if a project foregoes other qualification activities, including FAT is often a prudent decision. Why? Because if the primary risks associated with a piece of equipment revolve around budget and functionality, FAT might be the only qualification step needed. It provides a cost-effective means to ensure that the equipment aligns with expectations, making it a cornerstone of the qualification process.

-

Early Intervention for Success

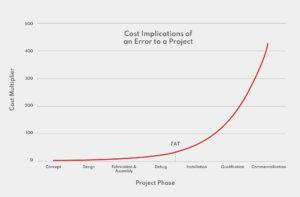

The impact of FAT on cost and schedule cannot be overstated. As depicted in Figure 2, design errors become exponentially costlier once equipment leaves the supplier’s facility. It’s far easier and cost-effective to rectify these issues at the source, long before installation.

The FAT milestone acts as a critical inflection point in the project, where design flaws, if any, can be identified and resolved promptly. The consequences of overlooking design errors at this stage can be detrimental, leading to extensive delays and budget overruns.

-

Foundation for Future Success

FAT is not just a standalone activity; it lays the groundwork for all subsequent qualification and commercialization endeavors. Here’s how FAT sets the stage for success:

- Integration: It streamlines integration with other manufacturing equipment and operations. Understanding how the tested equipment fits into the larger production line is crucial for smooth operations.

- Training: Operator and maintenance technician training begins with FAT. This early exposure allows them to become familiar with the equipment’s operation, minimizing hiccups during actual production.

- Installation Requirements: FAT helps confirm installation requirements, ensuring that the areas designated for the equipment within the manufacturing site are ready to receive and install it. This proactive approach saves time and resources.

- Insight Gathering: Much is learned beyond what’s apparent on the supplier’s floor during FAT. It offers insights into how the next phases of the project will unfold, allowing for adjustments and improvements.

The Blueprint for Success: Developing a Comprehensive Test Plan

Before the actual FAT, meticulous planning is paramount. A well-structured test plan serves as the blueprint for success. This plan draws from User Requirements, Equipment Specifications, and Key Performance Indicators, aligning all involved parties on the expectations and criteria for the testing process.

Key considerations in test plan development include:

- Defining Inspection and Testing Methods: It’s essential to specify how each inspection and test will be performed. This clarity ensures that everyone involved understands the process.

- Setting Target Dates: Agreeing on a target date for the FAT is crucial. It provides a clear timeline for the testing phase and helps keep the project on track.

- Simulating Automation Levels: Discussing how commodity inputs and outputs to the equipment will be handled to simulate the level of automation in the manufacturing facility is vital. This ensures that the testing environment mirrors real-world conditions.

- Structured Documentation: The test plan should be constructed in list form, providing dedicated spaces for documenting the results of each inspection. Additional spaces should be left for unforeseen inspections and notes.

- Approval Signatures: Including a signature page for approvals is not just a formality; it serves as evidence for milestone payments and ensures accountability.

With a comprehensive test plan in place, the FAT process becomes organized and transparent, minimizing potential roadblocks and misunderstandings.

Preparing for FAT: Ensuring Readiness

To ensure a smooth FAT process, a Pre-FAT visit might be necessary, depending on the size of the FAT team and the complexity of the equipment. This visit serves as a proactive step to guarantee that the equipment is ready for testing. It helps avoid the costs associated with travel and wasted time that could result from a large group showing up to an unfinished machine build.

The Day of Testing: FAT Execution

On the day of FAT, a team assembles on the factory floor, ready to put the equipment through its paces. Each team member is assigned specific tasks, and clear instructions are communicated for documenting results. It’s important to note that some organizations have strict protocols for note-taking, corrections, and even the color of pens used.

Moreover, it’s crucial to establish a common understanding of what constitutes a pass or fail. While strict adherence to specifications is essential in many cases, there may be instances where deviations are acceptable or even necessary. Using terms like “Acceptable” and “Not Acceptable” provides a more nuanced approach, accounting for these situations.

A Deeper Dive into FAT Checks

FAT checks can be categorized into two groups: static checks and dynamic checks.

Static Checks

Static checks are inspections completed while the equipment is not running and cover various aspects:

Safety: Verification that safety features, e-stop devices, and interlocks meet federal, local, and corporate standards is the top priority. Ensuring that energy within the system can be isolated and locked out is critical for personnel safety.

Layout: Checking that the equipment’s layout matches provided drawings is vital for integration with adjacent equipment within the production line. Operational considerations, such as guard door swings and user interface locations, are also examined.

General Construction: A close inspection of the equipment’s construction helps verify that it aligns with specified components, materials, fit & finish, and ease of maintenance.

Utilities: Confirming that provisions for handling utilities, such as compressed air and electrical supply, meet project requirements is essential. This includes checking parameters like size, pressure, consumption, voltage, and fuse ratings.

Documentation: Evaluating the progress of documentation preparation, including OEM manuals, spare parts lists, operating manuals, and control programming, ensures that comprehensive records are in place.

Dynamic Checks

Dynamic checks, on the other hand, are inspections completed while the equipment is running. They encompass:

Rate Verification: Verifying that the equipment can operate at the required speeds for a sustained period without faults ensures that it meets production demands.

Quality Checks: Ensuring that the equipment does not introduce damage or quality defects to the product is crucial for maintaining product integrity. This often involves inspecting the outputs from rate verification to identify any defects.

Functional Provisions: Verifying that the equipment performs its intended tasks and behaves correctly under different conditions is fundamental. This includes testing start-up procedures, handling characteristics, jogging, homing functions, and alarms/fault reporting methods.

Induced Failure Testing: This testing evaluates the equipment’s ability to respond to and recover from typical fault conditions. It helps assess how resilient the equipment is in real-world scenarios. The process involves:

- Starting the equipment to simulate production conditions.

- Generating typical fault conditions intentionally.

- Observing the equipment’s response and error messages on the Human-Machine Interface (HMI).

- Demonstrating the recovery from the failure and the return of the machine to normal running condition.

- Documenting the procedure for recovery from each failure condition.

- This sequence is repeated for various typical fault conditions, with detailed records of responses and recoveries.

In Conclusion: The Significance of Factory Acceptance Testing

In conclusion, Factory Acceptance Testing is not just a checkbox in the equipment qualification process; it’s the heartbeat of success. A well-executed FAT can uncover design flaws, streamline integration, ensure safety, and set the stage for a seamless production process. By conducting a thorough FAT, manufacturing companies can address potential issues early, saving both time and money. It’s the first step in a journey toward equipment qualification, setting the stage for subsequent phases and ensuring that the end result aligns with project objectives.