The Essential Role of Packaging in the Food & Beverage Manufacturing Sector

In your next product purchase, whether it be the latest soft drink or juice or a simple carton of milk, it is imperative to direct attention to the packaging. Extensive consideration has been given to the container, mirroring the thoughtful approach applied to the product it houses. The meticulous design of the packaging encompasses various facets, ranging from environmental sustainability to the communication of quality and brand craftsmanship. Additionally, functional considerations, such as enhancing the product’s lifespan, have been taken into account. Despite its pervasive presence in our daily lives, the significance of packaging is often overlooked. However, within the food and beverage manufacturing industry, engineers, operators, and workers alike dedicate considerable deliberation to the packaging, recognizing its integral role in the overall product presentation.

Protection, Differentiation, and Convenience

When it comes to food and beverage the fundamental purpose of packaging is protection. When food and beverages are manufactured and processed, they need to stay fresh and uncontaminated. Packaging serves as a barrier, ensuring the product within remains in its intended state till it reaches the consumer.

Beyond protection, packaging plays a vital role in brand differentiation. With hundreds of products lining the shelves, a distinct package design helps products stand out. This isn’t just about the logo or color scheme; it’s about conveying the brand’s story, values, and promise to the consumer.

Lastly, let’s not forget convenience. From resealable packages to plastic bottles that don’t break when dropped, packaging innovations make consumers’ lives easier.

Behind the Scenes: Packaging’s Technical Requirements

To the untrained eye, packaging might seem simple. But delve deeper, and you’ll see it’s a finely tuned science. The right packaging material should offer stability, ensuring the food or beverage inside has a long and safe shelf life. It should not alter the taste, flavor, or effectiveness of the product.

Also, the packaging must be suitable for high-speed manufacturing, especially since many of these products are manufactured across various locations to cater to vast consumer bases.

A Closer Look at Packaging Tiers

Packaging isn’t a one-size-fits-all solution. Depending on the product and its intended distribution channel, there are different tiers:

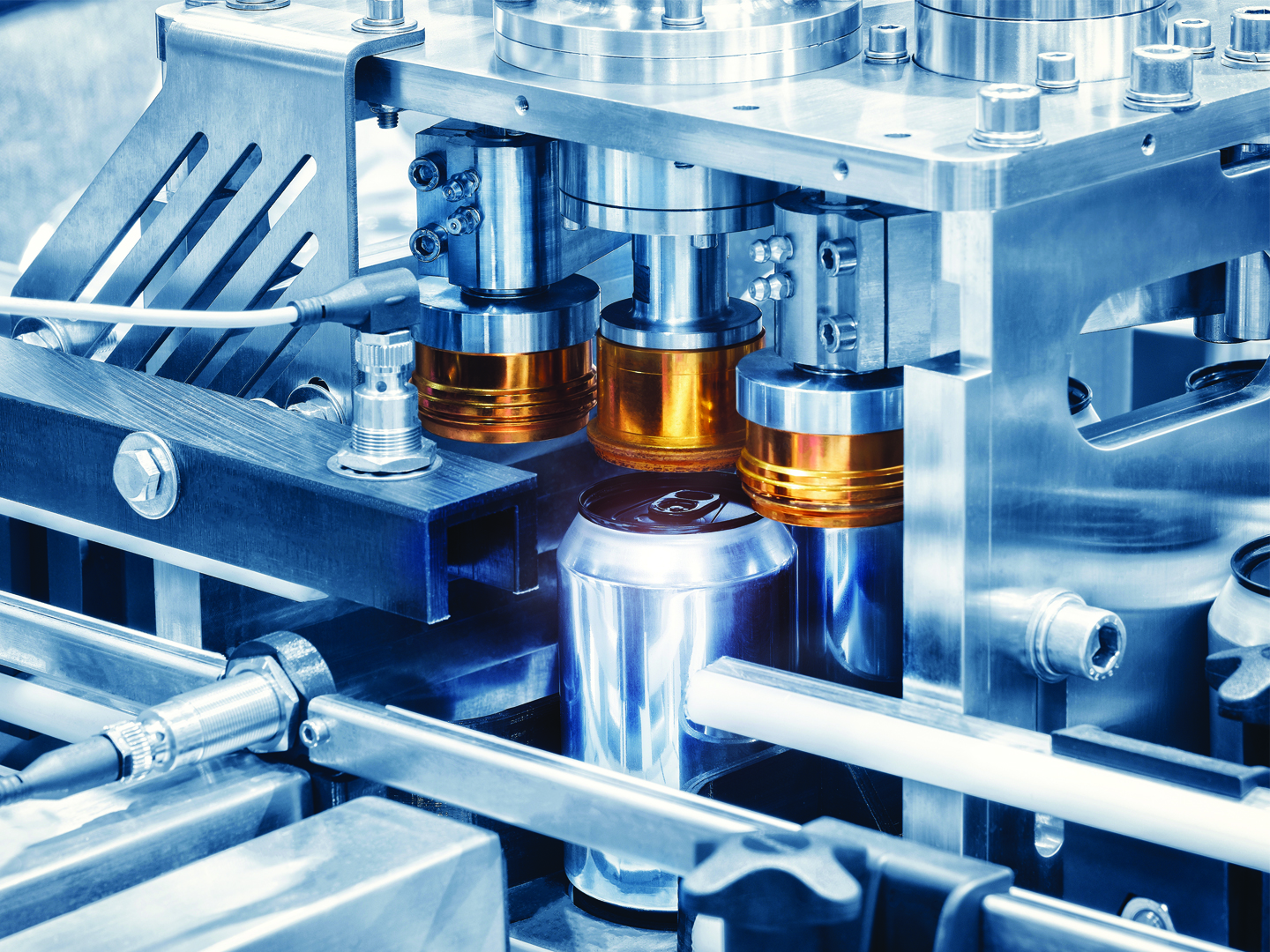

- Primary Packaging: This is the main container holding the product, such as a bottle or can.

- Secondary Packaging: This includes elements like labels, closures, and cartons which further protect and enhance the primary packaging.

- Tertiary Packaging: Here, we’re talking about corrugated boxes, or larger, logistical packaging – think pallets, wraps, and straps, which help in the bulk transportation of products.

Understanding Packaging in the Manufacturing Equation

For Consumer Product Companies (CPGs), the choice of packaging isn’t arbitrary. Several factors influence this decision:

- Targeted price point and product category.

- Size and cost of ingredients.

- Packaging costs vis-a-vis the final product price.

- Manufacturing and distribution expenses.

- Intended profit margins.

Manufacturing speeds, driven by product demand, also influence packaging decisions. The faster a line runs, the more cost-effective it becomes. Hence, packaging plays a pivotal role in determining the Cost of Goods Sold (COGS) for many products.

The Journey of Packaging

From the time a product is manufactured until it reaches the consumer, packaging serves multiple roles:

- It ensures the product is transported safely from the manufacturing site to the warehouse.

- It withstands the rigors of distribution, from the warehouse to retail stores.

- On the store shelf, it acts as a silent salesman, enticing consumers to make a purchase.

- Finally, it ensures the product reaches the consumer’s home in pristine condition.

In Conclusion

The next time you pick up a product, take a moment to appreciate the packaging. It’s a culmination of research, design, science, and manufacturing logistics – all working in tandem to ensure the product inside is fresh, safe, and appealing. For the food and beverage manufacturing industry, it’s a testament to their commitment to delivering the best to consumers.

Joe Norris

New Product Development and Technical Service

Joe Norris boasts a stellar career spanning over four decades in the packaging and product development arena. Serving for ten years at SmartSkin Technologies in Fredericton, Canada, he’s an expert in New Product Development and Technical Service. Prior to this, Joe held pivotal roles at The Coca-Cola Company, both as Principal Engineer for Global Packaging R&D in the Greater Atlanta Area and earlier as a Packaging Engineer in Atlanta and London. His keen insights have influenced early concept ideation, design, and alpha engineering, with a particular emphasis on the commercialization of North American aluminum bottles and their resealable closures.

Joe’s journey also includes an impressive 15-year tenure at Colgate Palmolive Co in New York City and Piscataway, New Jersey. Initially, he championed package engineering leadership for top US brands, notably playing a key role in the successful launch of Total toothpaste in 1997. Later, he spearheaded a team advancing global brand and package technology innovation, securing the Global Technology Award in 2001 for dual tube commercialization.

A testament to his innovative spirit, Joe has an impressive portfolio of 18 issued patents with both Colgate-Palmolive and The Coca-Cola Company. His remarkable contributions to the industry underline his expertise and commitment to packaging and product development.