Commissioning Equipment with SmartSkin: Optimizing FAT/SAT process

Introduction: SmartSkin as an ideal solution for line commissioning:

Factory Acceptance testing provides an efficient means for both manufacturers and end-users to verify that new equipment meets all agreed-upon specifications. This process ensures that any issues are flagged and resolved before equipment reaches the client’s site and that timelines are maintained. Site Acceptance Testing is similar to the FAT process but it takes place ON the site after equipment has been delivered and installed (usually also after FAT has been carried out). In order to efficiently maintain budgets and timelines, both verification processes are equally important.

As SmartSkin’s technology is catered to capturing line data and providing insights that facilitate line assessments, its capabilities greatly suit line commissioning initiatives. Using container twins that can imitate the specifications of a container, real-time insights can be collected that indicate whether there are issues on the line that need addressing.

Understanding SmartSkin’s capabilities in optimizing set-up processes

-

Rapid Validation of Line Setup:

SmartSkin can quickly establish baseline performance metrics during commissioning, ensuring the line is set up correctly from the start. It identifies potential problems, such as misalignments, excessive forces, or bottlenecks, before full-scale production begins.

-

Proactive Issue Detection

By monitoring forces and stress across the line, SmartSkin pinpoints sources of adverse forces, preventing damage to packaging, equipment, or products. This reduces the risk of costly downtime or production delays during initial operations.

-

Optimized Changeover

SmartSkin helps optimize line settings during changeovers to accommodate different product types, reducing the learning curve and minimizing waste.

-

Benchmarking and Long-Term Improvement

It provides a detailed performance benchmark that can be used to measure improvements and deviations as the line scales up. This ensures that the commissioning process sets the line on a path to sustained efficiency and quality.

-

Data-Driven Decisions

SmartSkin’s real-time data and visual line maps allow engineers and operators to make immediate, informed decisions during the commissioning process. It provides actionable insights, enabling rapid troubleshooting and reducing guesswork.

-

Minimized Start-Up Costs

By reducing downtime, defects, and inefficiencies during commissioning, SmartSkin allows you to make all products efficiently, saving time and costs but maintaining high standards of quality.

Key Takeaways

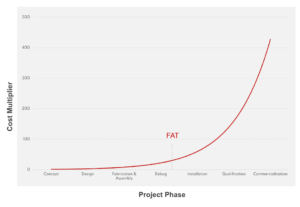

The longer costs associated with damage remain hidden, the more dramatically their effect increases. The longer an error goes undiscovered during design and manufacturing of equipment, the more costly it becomes down the pipeline both financially and for scheduling.

To maintain product standards and ensure efficient deployment processes, SmartSkin’s globally recognized technology provides customers the necessary assistance through this meticulous process.