SmartSkin Pharmaceutical Formats

SmartSkin’s digital surrogates for vials, syringes, cartridges, and ampoules provide real-time data on pressure, shock, spin, tilt, seal tightness, and closure integrity—empowering better quality, efficiency, and safety.

SmartSkin Solutions

One Platform. Every Format. Zero Guesswork.

SmartSkin Technologies provides a unified solution for monitoring vials, syringes, cartridges, and ampoules packaging. Our smart container twin formats mimic real drug containers and detect critical forces—pressure, shock, spin, tilt, and seal integrity—in real time.

These insights from the perspective of a container helps pharmaceutical manufacturers minimize breakage, accelerate root cause analysis, and protect product quality across the entire filling and packaging line.

SmartSkin Solutions

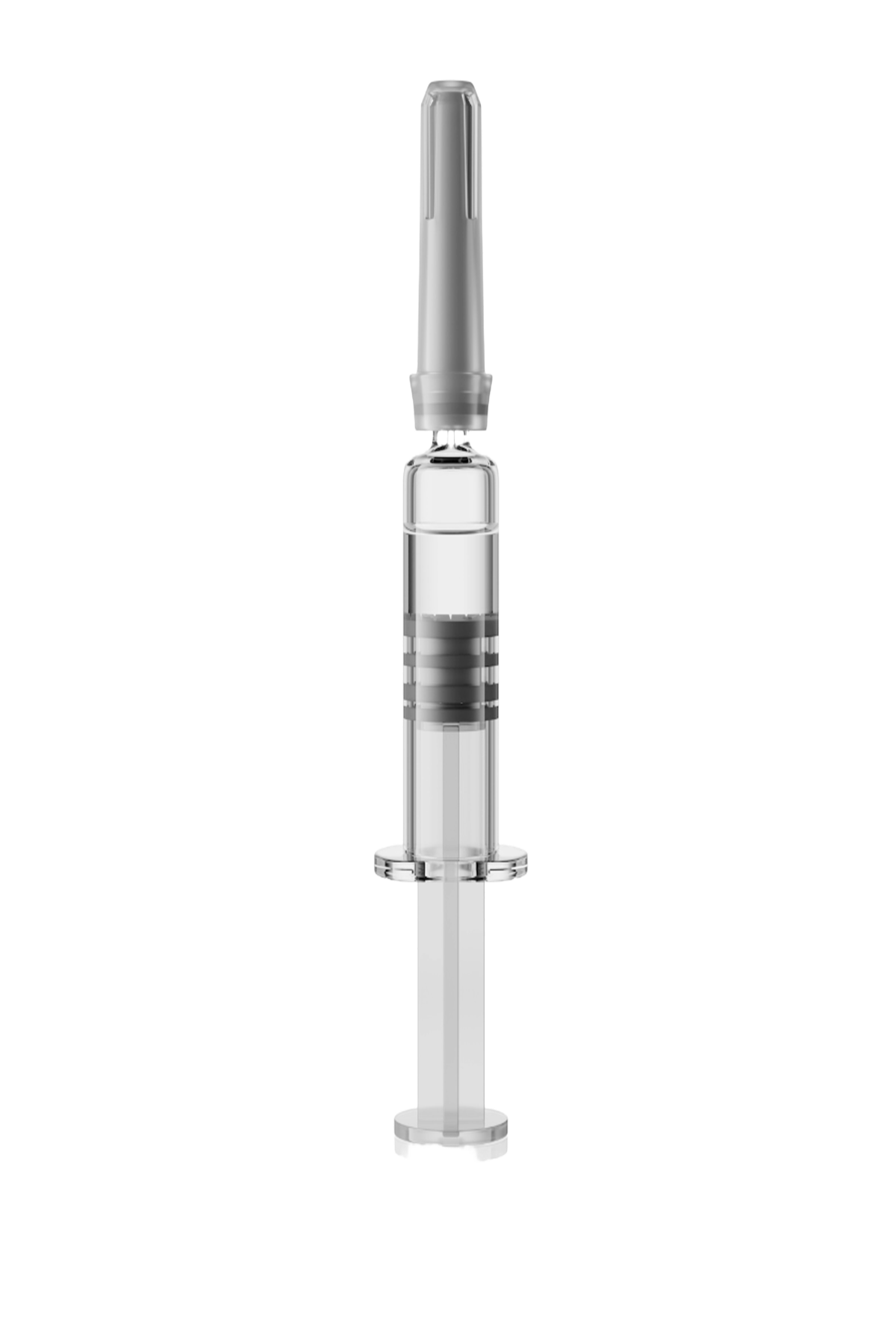

Designed to Your Containers Exact Specifications

At SmartSkin, we create high-fidelity container twins that precisely replicate the physical characteristics of your primary packaging—down to the exact specifications. Whether it’s vials, syringes, cartridges, ampoules, or a custom-designed container, each container twin is engineered to match your unique format with uncompromising accuracy.

These advanced replicas allow for seamless integration into your existing lines, enabling real-time monitoring and actionable insights without interrupting production or risking valuable product.

Key Benefits

Real-time Container Data

Capture pressure, shock, spin and tile in real-time as containers move through your line.

One Solution

Support variations in sizes and specifications for vials, syringes, cartridges, and ampoules without needing separate tools or workflows.

Full Visibility

Measure pressure, shock, spin, tilt, seal tightness, and closure integrity to understand forces on your line at every critical step.

Prevent Breakage

Identify damaging forces before they lead to container failure, quality rejects, or production delays.

Root Cause Analysis

Quickly trace defects to specific machines or steps—no more trial and error.

Protect Quality

Ensure container the highest packaging quality and closure integrity and prevent product loss or contamination.

Improve Equipment

Use data to setup, calibrate and optimize machine settings for gentler, more precise container handling.

Designed for Pharma

SmartSkin container twins match the shape and profile of real formats for seamless integration in to the existing line.