Data-driven pharma manufacturing

Transform your pharmaceutical production line with real-time container handling and equipment performance data – directly from your products’ perspective.

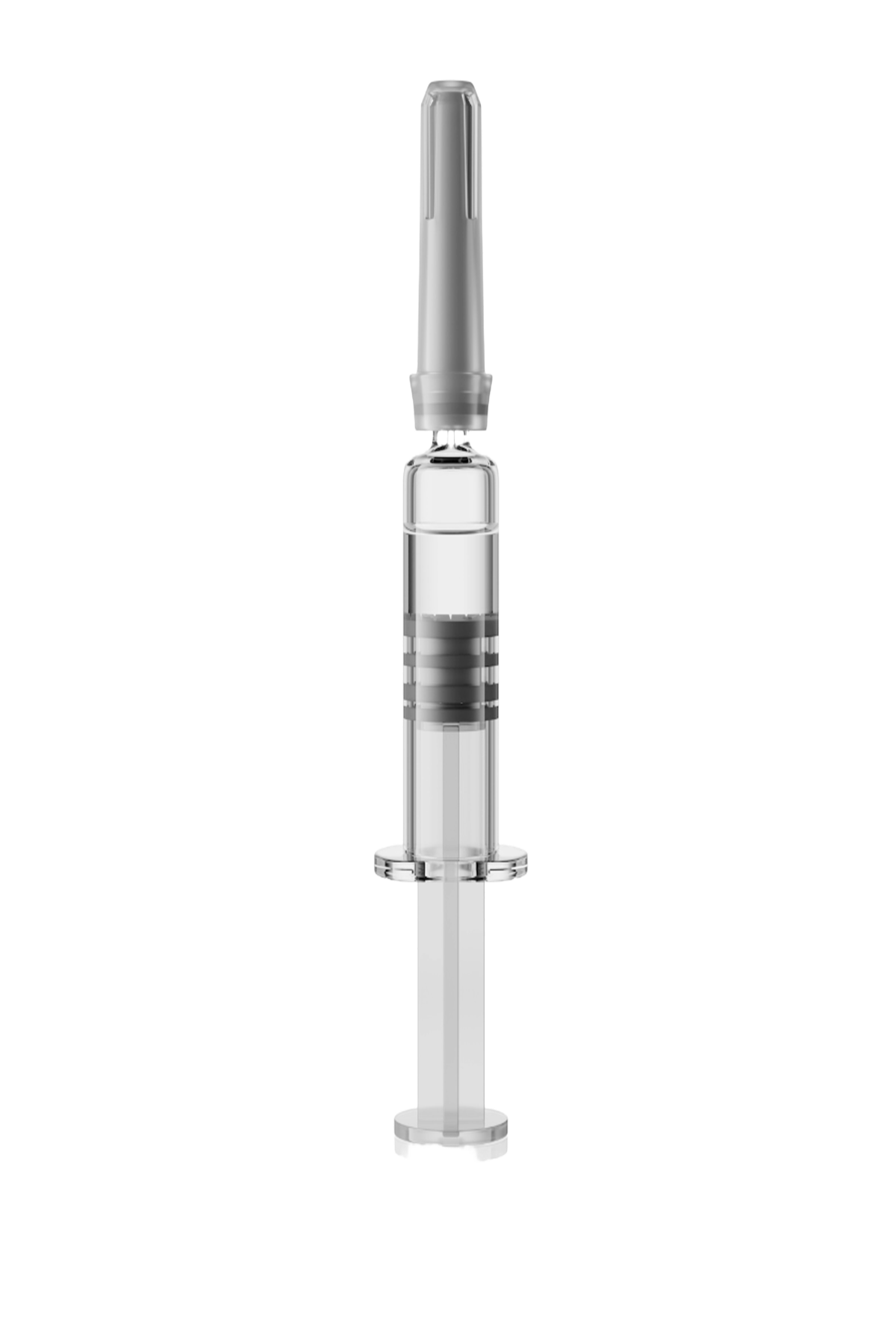

Protect your primary packaging at every stage

Don’t let glass damage be the first sign of line issues. Get unique insight into what your containers experience at every stage of filling and packaging to optimize equipment performance.

With real-time container handling data directly from your products’ perspective, you can instantly identify and mitigate risk areas, verify optimal setup, and accelerate maintenance and continuous improvement activities.

BENEFITS

User friendly

Get instant insight into handling performance as soon as you receive your system. User-friendly and easy-to-operate, your entire team can leverage the technology to solve their most pressing challenges.

Real-time data

Robust data analytics, including trend analysis and data visualization help you understand patterns associated with container damage and defects, part wear and equipment setting issues.

Accurate and reliable

Make data-driven decisions to mitigate risks. With reliable, quantifiable data on the damaging forces your products experience, you can enhance QRM and continuous improvement strategies.

Easy setup

All SmartSkin solutions arrive ready to go, so you don’t have to worry about complicated integrations or equipment modifications and our team of technical experts is always here to help.