Optimize Packaging Operations

SmartSkin helps operations leaders improve packaging line efficiency, reduce container damage, minimize downtime, and meet production targets with consistent quality—backed by real-time container-level data.

SmartSkin Solutions

Reduce Waste. Improve Efficiency.

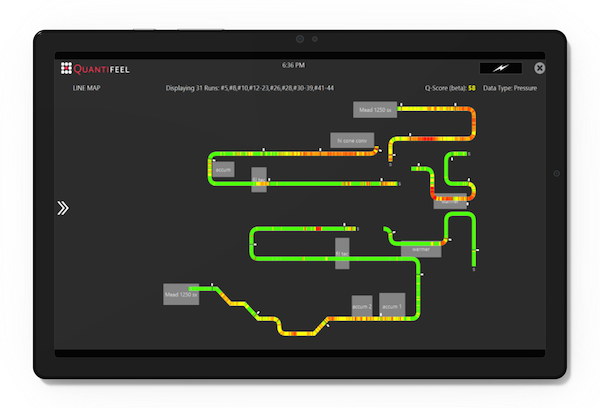

SmartSkin’s sensor-enabled container twins provide real-time insights into the forces impacting bottles, cans, and jars across your line. With instant visibility into pressure, shock, spin, tilt and scuffing, operations teams can detect problem areas, eliminate breakage, and stabilize performance.

Use SmartSkin to hit daily production goals with less scrap, fewer delays, and greater packaging consistency.

Benefits

Operational Efficiency Through Smart Data

SmartSkin empowers operations teams to run tighter, cleaner, more consistent packaging lines. Instead of relying on trial and error, your team can use data from sensor-equipped container twins to visualize how containers interact with equipment in real time. Whether reducing unplanned downtime, eliminating breakage, or optimizing throughput, SmartSkin equips operations with actionable intelligence to stay on target.

Fewer slowdowns. Less waste. Better control over every shift.