Engineered for Packaging Precision

SmartSkin gives engineers real-time container-level data to optimize packaging line design, validate changeovers, streamline commissioning, and reduce packaging stress—enhancing efficiency without compromising product integrity.

SmartSkin Soluti0ns

Design Smarter, Operate Smoother

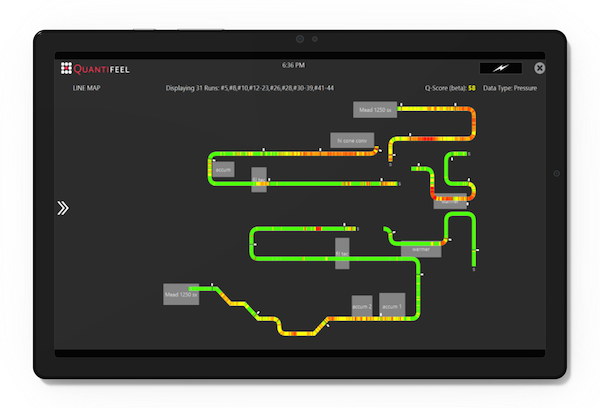

SmartSkin’s sensor-enabled container twins help engineers understand how packaging interacts with equipment across the line. Whether launching new formats, validating OEM performance, or improving line layout, you’ll get actionable data on pressure, impact, spin, tilt, and scuffing—no guesswork required. Use SmartSkin to validate design assumptions, fine-tune performance, and speed up FAT/SAT and line ramp-up.

Benefits

Engineering Intelligence. Container-Level Precision.

Engineering teams face the challenge of delivering high-speed, low-waste packaging lines that can handle increasing product and container complexity. SmartSkin bridges the gap between line design and container behaviour, offering data-driven visibility into every interaction.

By simulating real containers with embedded sensors, SmartSkin gives engineers an inside look at pressure points, impact zones, and motions your container experiences—critical for validating designs, troubleshooting issues, and optimizing new equipment or packaging formats.